The Importance of Prototype Mold Making Suppliers in Modern Manufacturing

In today's highly competitive market, efficient manufacturing processes are critical to the success of any business. At the heart of this efficiency lies the work of prototype mold making suppliers. Companies like DeepMould.net are vital players, offering essential services that drive innovation and development in various industries. This article delves into the significance of prototype mold making and how these suppliers contribute to enhancing productivity and product quality.

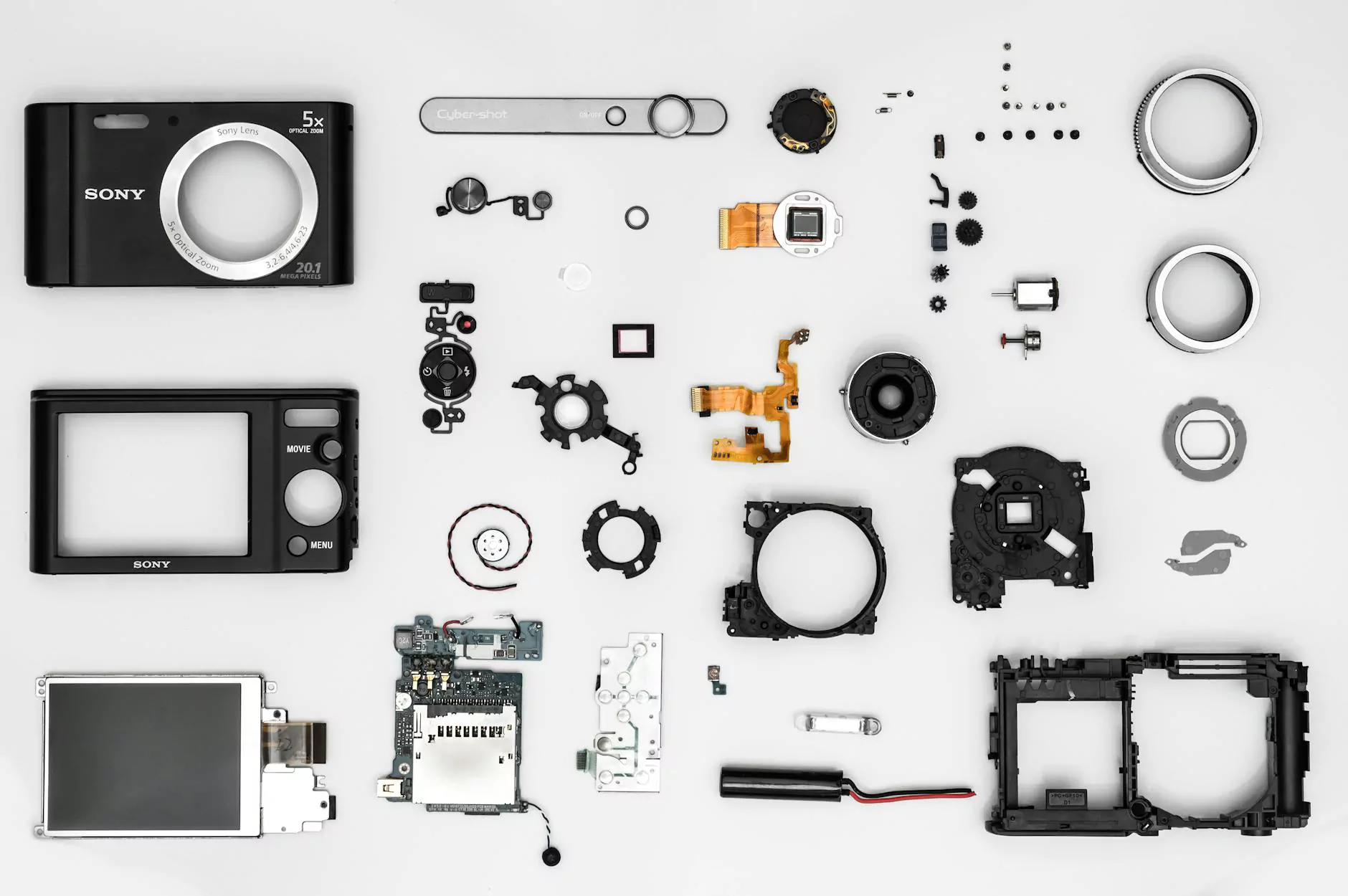

What is Prototype Mold Making?

Prototype mold making refers to the process of creating molds for producing prototypes of parts and products. These molds are essential in the manufacturing sector, especially for businesses that rely on precision and quality. Unlike ordinary molds, prototype molds are designed with the intent to create a small number of parts for testing before full-scale production begins. This approach minimizes risks associated with design flaws and production errors.

Why Choose a Prototype Mold Making Supplier?

Opting for a specialized prototype mold making supplier offers several advantages:

- Expertise in Design: Suppliers are equipped with the knowledge and tools needed to create high-quality molds, tailored to your specific requirements.

- Faster Time to Market: Rapid prototyping helps businesses test their products quicker, allowing for timely revisions and adjustments before full-scale production.

- Cost Efficiency: Using prototype molds can significantly reduce the expenses associated with making design changes during mass production.

- Variety of Materials: A proficient supplier can work with various materials, ensuring that the final product meets all functional and aesthetic criteria.

The Role of DeepMould.net as a Prototype Mold Making Supplier

As a renowned prototype mold making supplier, DeepMould.net stands at the forefront of innovation in mold manufacturing. We offer a wide range of services that cater to the unique demands of our clients, ensuring that they receive not just a product, but a comprehensive solution.

Services Offered by DeepMould.net

DeepMould.net provides an extensive list of services essential for businesses looking to develop prototypes:

- Custom Mold Design: Our team collaborates with clients to create molds that reflect their specific requirements, ensuring precision and functionality.

- Rapid Prototyping: Utilizing advanced technologies, we expedite the prototyping phase, allowing clients to test their designs swiftly.

- Mold Fabrication: With state-of-the-art machinery, we fabricate molds that support various production processes, from injection molding to CNC machining.

- Material Selection: We assist clients in selecting the right materials based on their product specifications and functional needs.

- Quality Assurance: Quality is at the heart of what we do. All molds undergo rigorous testing to ensure they meet industry standards.

Benefits of Working with a Top-Tier Prototype Mold Making Supplier

Partnering with a high-quality prototype mold making supplier like DeepMould.net can provide your business with considerable advantages, including:

- Enhanced Product Quality: Our precise engineering and manufacturing processes lead to improved product quality, which is crucial for maintaining a competitive edge.

- Innovative Solutions: We leverage the latest technologies and methodologies to offer innovative solutions that meet evolving market demands.

- Scalability: Our services can easily adapt as your business grows, making the transition from prototype to full production seamless.

The Process of Working with DeepMould.net

Understanding the workflow at DeepMould.net is crucial for potential clients. Here’s a step-by-step guide to how we operate:

1. Initial Consultation

We start with an initial consultation to discuss your requirements, timelines, and expected outcomes. This understanding helps us tailor our services to fit your needs.

2. Design Phase

Our skilled designers will create detailed designs of the molds. Using CAD software, we ensure that every aspect aligns with your specifications.

3. Prototype Development

Once the designs are approved, we manufacture the prototype molds. This involves selecting the right materials and using advanced production techniques.

4. Testing and Evaluation

We conduct rigorous testing of the molds to identify any issues and to ensure they perform as intended during prototyping.

5. Final Delivery

Upon successful testing, we deliver the molds along with necessary documentation, ensuring that you have everything needed for the next steps in production.

Choosing the Right Prototype Mold Making Supplier

When selecting a prototype mold making supplier, several factors should be considered:

- Experience: Choose a supplier with a solid track record in mold making and a portfolio showcasing previous work.

- Technology and Tools: Ensure the supplier uses modern technology and equipment to produce high-quality molds.

- Customer Support: A responsive and knowledgeable customer service team can help address any concerns or questions during the process.

- Reviews and Testimonials: Look for feedback from previous clients to gauge the reliability and workmanship of the supplier.

Case Studies: Successful Partnerships with DeepMould.net

To illustrate the effectiveness of partnering with a proficient prototype mold making supplier, let's explore a few case studies:

Case Study 1: Automotive Component Prototyping

A leading automotive company approached DeepMould.net for the development of a new component. Through iterative prototyping, we quickly identified design flaws and refined the component. This collaboration not only resulted in a flawless product but also saved substantial time and costs.

Case Study 2: Medical Device Innovation

In the medical sector, precision is paramount. DeepMould.net collaborated with a medical device manufacturer to create a prototype for a life-saving device. Our expertise in materials and rapid prototyping led to a successful device that met all regulatory requirements and achieved the desired outcome.

The Future of Prototype Mold Making

As industries continue to evolve, the role of prototype mold making suppliers will become increasingly crucial. Technological advancements, such as 3D printing and improved CNC machining, are transforming how molds are created. Suppliers like DeepMould.net are at the forefront of these innovations, continuously adapting to meet industry demands.

Conclusion

In conclusion, choosing the right prototype mold making supplier can significantly impact your business's success. With expert knowledge, advanced technology, and a dedication to quality, DeepMould.net exemplifies the standards of excellence in this field. By understanding the critical role of prototype mold making and leveraging the services offered by specialized suppliers, businesses can streamline their production processes, enhance product quality, and ultimately achieve a competitive edge in the market.

For manufacturers looking to innovate, DeepMould.net stands ready to be your partner in success. Contact us today to learn more about how we can support your prototyping needs and help you turn your ideas into reality.